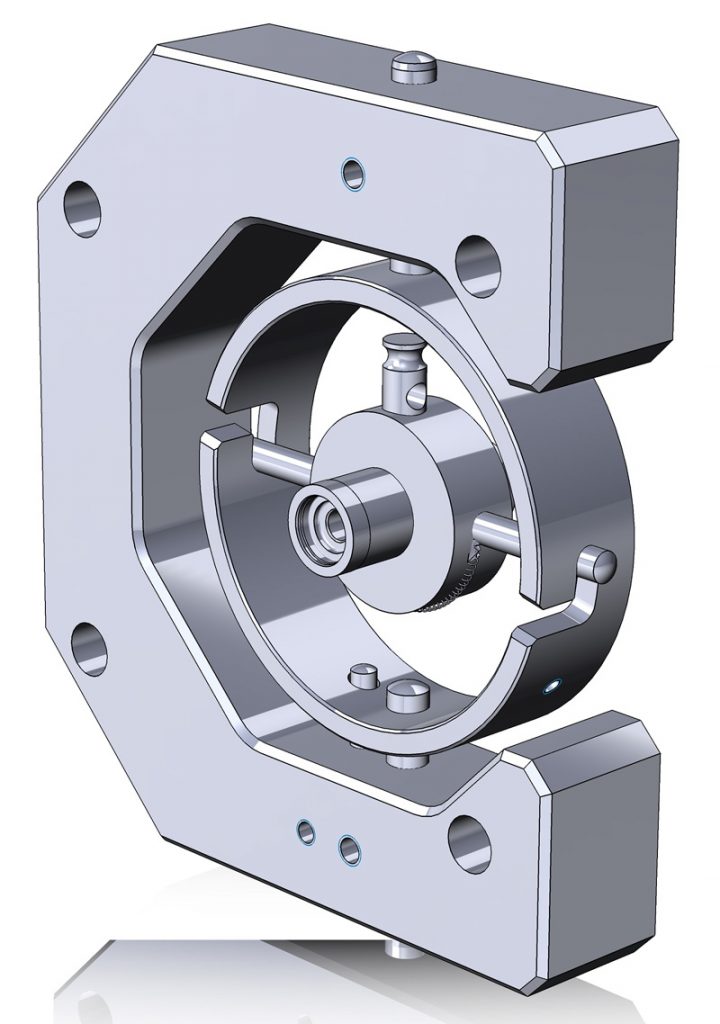

Setting Master for calibrate Connecting Rod coordinate

measuring machine

Critical measurement: CC distance between the holes and

the diameter of the holes

Material: Hardened Tool Steel

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Automotive Engine Manufacturer

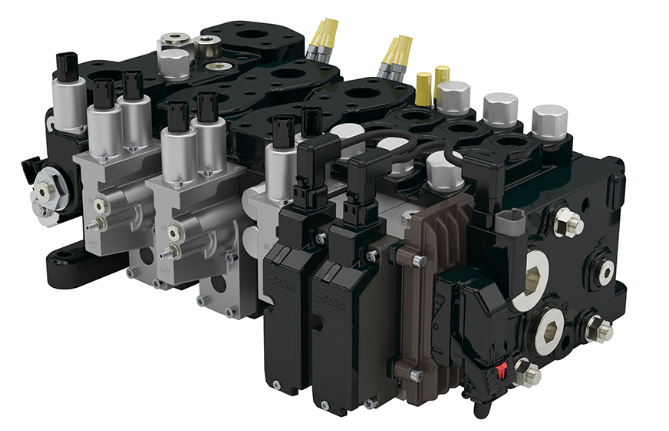

Customer specified Guide Plate for exact settings in advanced production process

Material: Hardened Tool Steel

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Advanced Hydraulic System Manufacturer

Machine specified Setting Master for calibrate

precision grinding operations

Material: Tungsten Carbide with soldered spheres

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Indexable Inserts Manufacturer

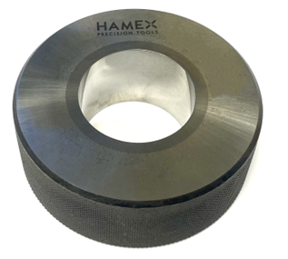

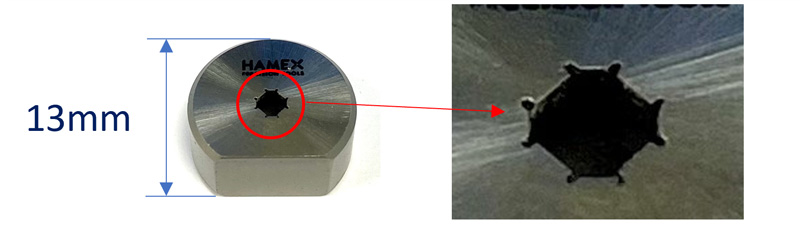

Setting Master for exact internal measuring

Material: Tool Steel with brazed Tungsten Carbide insert

Knurled outer surface for good grip

Tolerances: +/- 0,001mm // +/- 0,000039inch

Application: Setting of measuring equipment

Setting Master for exact complicated measuring

(No photos allowed, but guaranteed state of the art

Setting Masters very few companies capable to

manufacture)

Material: According to specification

Tolerances: +/- 0,001mm // +/- 0,000039inch (min)

Customers: Military Weapons & Ammunition Manufacturers

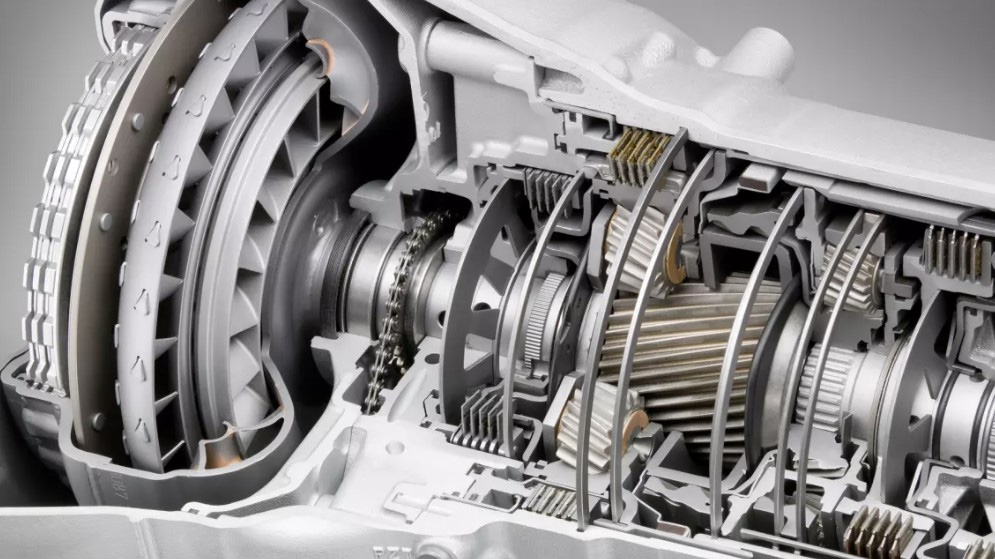

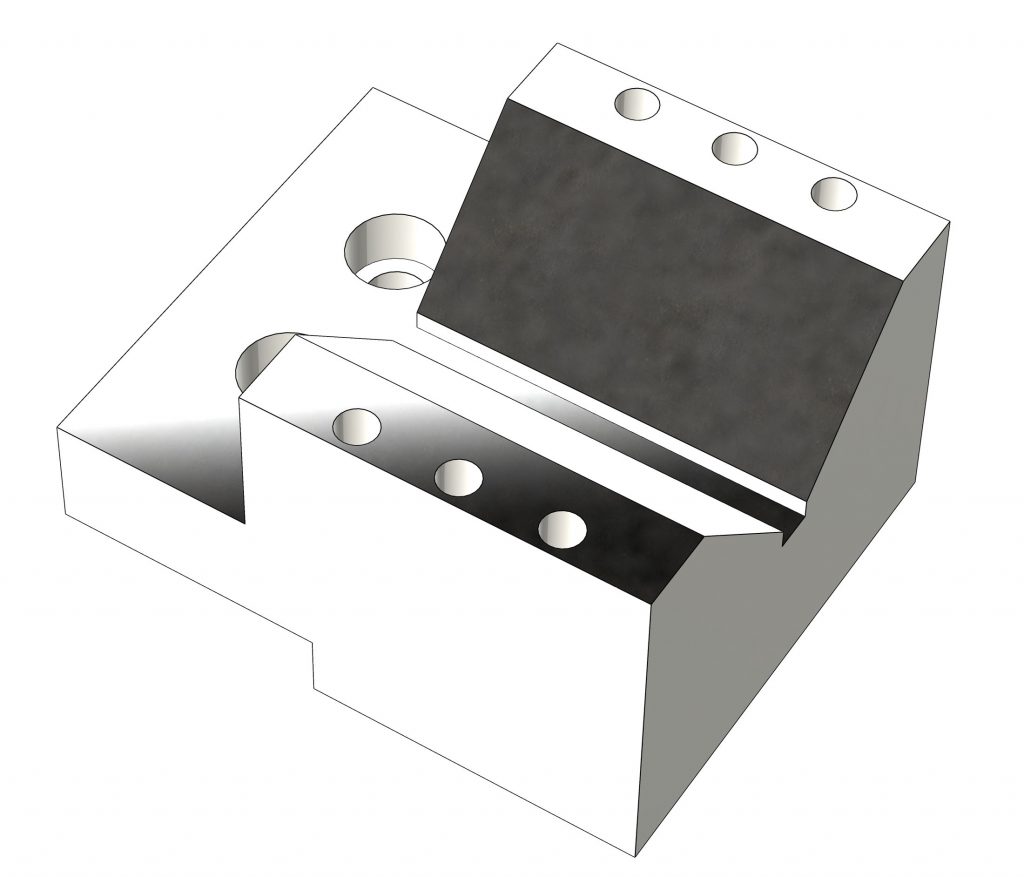

Fixed Gauge with dual measuring verification

#1 Diameter

#2 Splines

Material: Handle in Tool Steel, Brazed Tungsten Carbide Spline Insert

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Automotive Gearbox Manufacturer

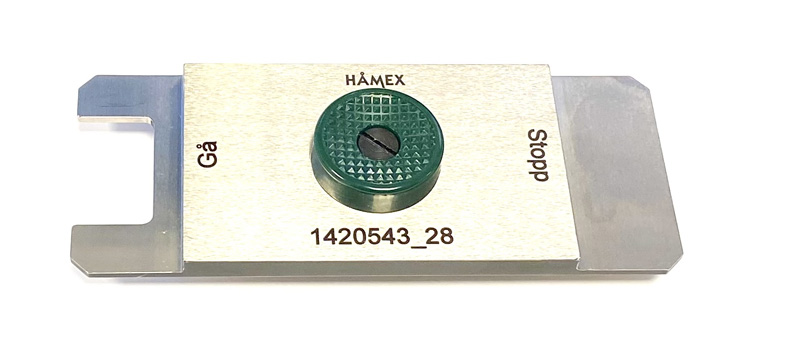

Go –No Go Fixed Gauge

Material: Tool Steel with adapted holding knob

Tolerances: +/- 0,005mm // +/- 0,000197inch

Customer: Advanced Hydraulic Manufacturer

Fixed Gauge for product shape verification

Material: Tool Steel

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Medical Equipment Manufacturer

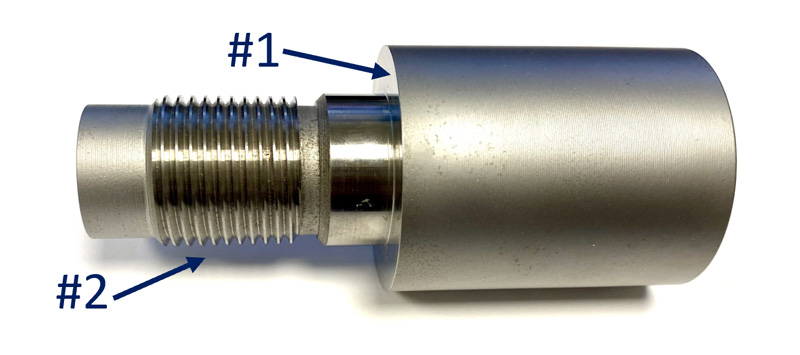

Fixed Gauge with dual measuring verification

#1 Diameter

#2 Threads

Material: Tungsten Carbide

Tolerances: +/- 0,001mm // +/- 0,000039inch

Customer: Automotive Manufacturer

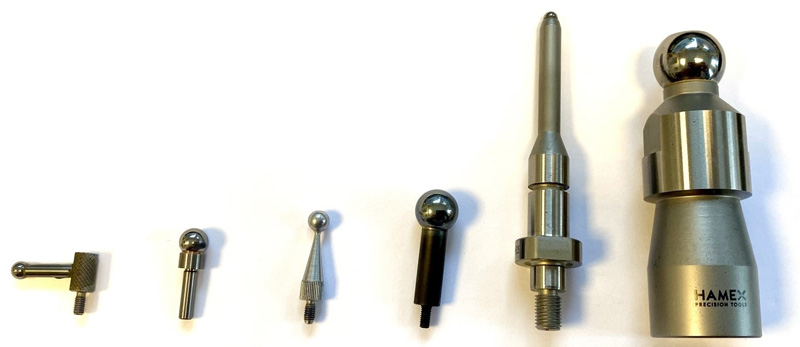

Customer specified probes with soldered sphere

Probes in different materials with various designs and sizes

Application: Measuring equipment

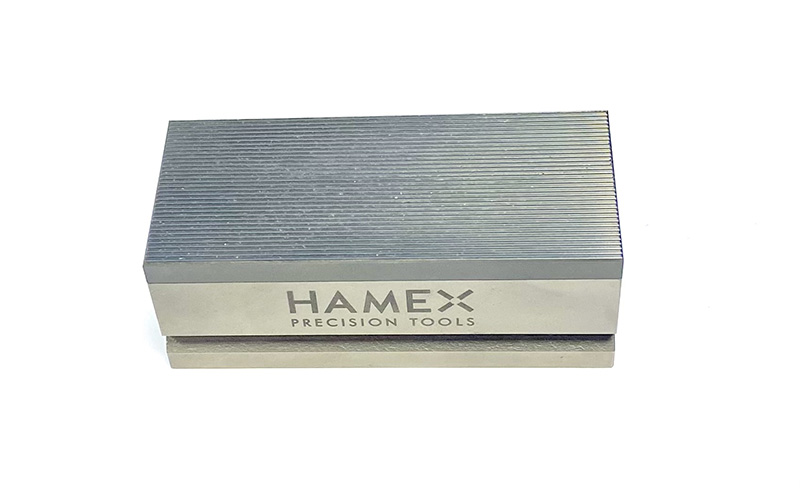

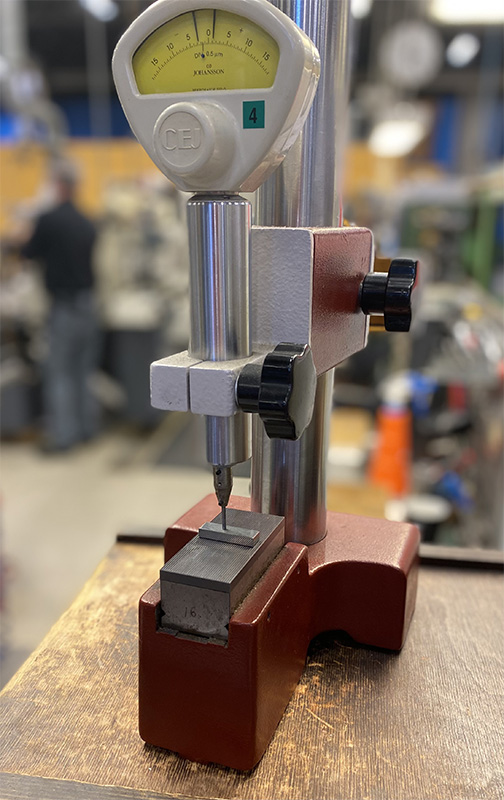

Square or Round Anvils in different sizes and materials.

Surface according to customer specifications.

Application: Comparator Stand

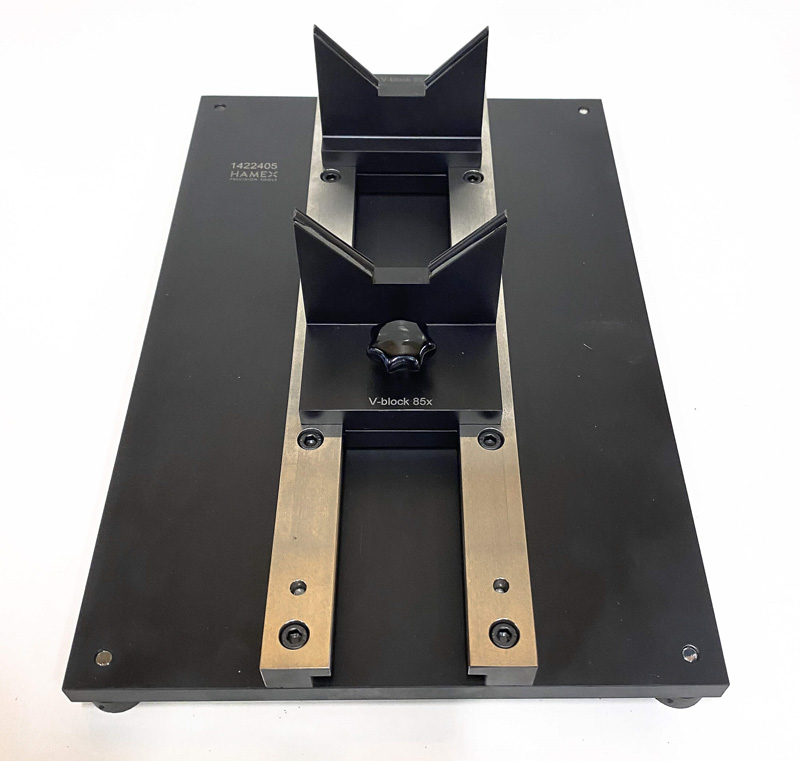

Fixture for Roundness Measuring

Fixture for Wire EDM

Fixture for Honing